| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Suneast |

| Model Number : | SEMI-E3 |

| Certification : | CE、ISO |

| Price : | Negotiable |

| Payment Terms : | T/T |

| Delivery Time : | 25~50 days |

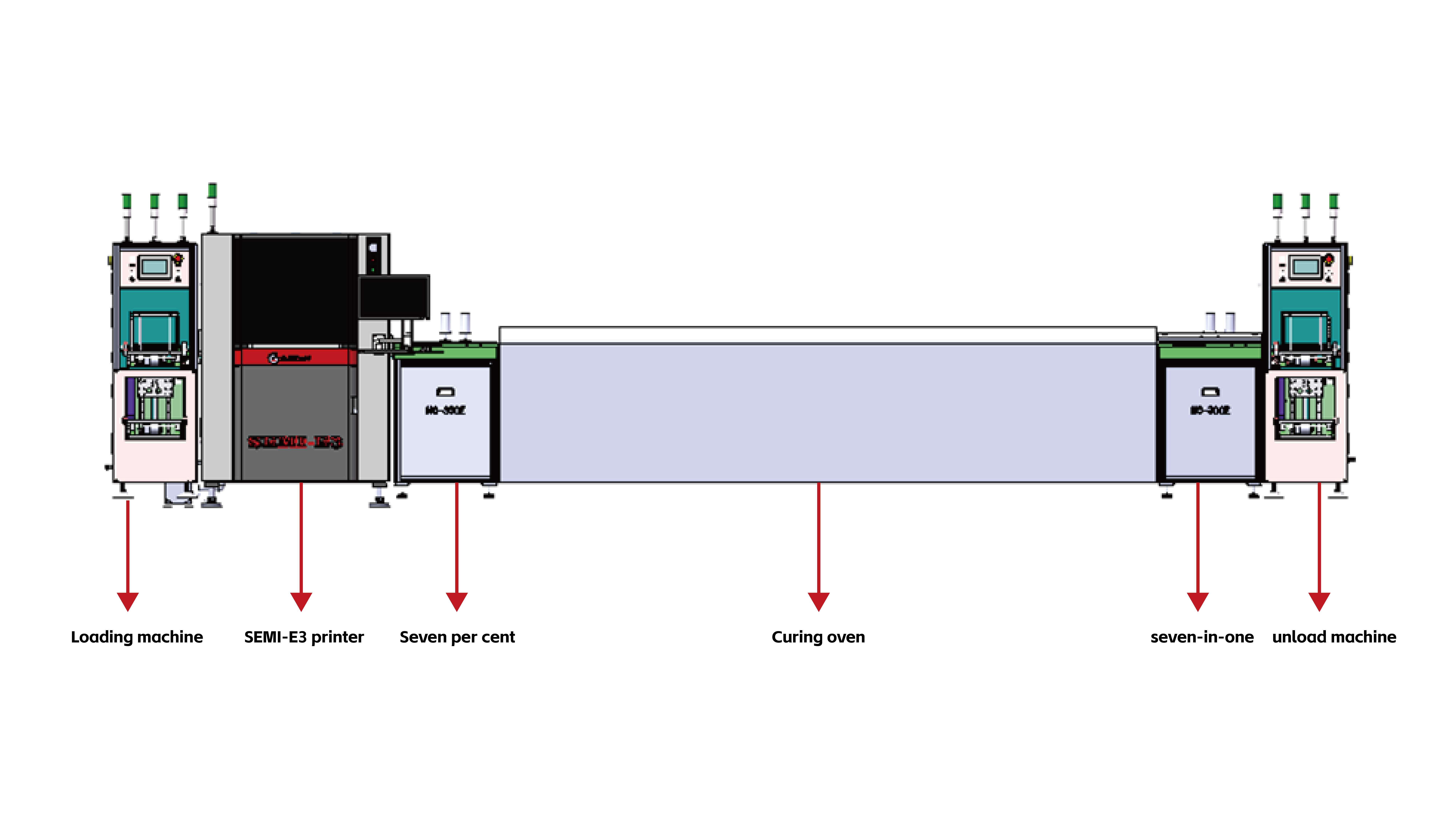

Gold/Silver Paste Fully Automatic Semiconductor Printer

Adopt screen printing to print conductor paste, resistor paste, or dielectric paste onto ceramic substrates, after high-temperature sintering, these materials will form a firmly adhered film on the ceramic circuit board. After repeated multiple times, a multi-layer interconnected circuit which contains the resistors or capacitors will be formed. Suneast gold paste/silver paste fully automatic semiconductor printer adopts modular design and humanized structure, which can cope with high-precision requirements for film thickness uniformity such as gold paste, conductive silver paste, R glue, and glass base glaze.

Application:

Suneast Semiconductor Fully Automatic Screen Printer SEMI-E3 is widely used in the printing process of semiconductor devices, thermal print heads, ceramic capacitors, ceramic circuits, filters, potentiometers, dielectric antennas, RFID, LTCC, MLCC, sensors, piezoelectric ceramic components, chip components and other products.

Features and advantages:

◆ The new appearance design is beautiful, stable and meets the standards of ergonomics and human engineering.

◆ For debugging for necessary parameters during the process production, it is equipped with SPI online function, so that the material replacement and printing quality can be truly intelligently controlled.

◆ New and advanced UI software interface, with portable and smart software, and the easy-to-understand and easy-to-operate Chinese and English systems make the product easy to use and has no geographical boundaries.

◆ The newly upgraded optical path system, in addition to ensuring good MARK recognition capabilities, also meets the traceability requirements required by the current intelligent line.

◆ The dust-proof design meets the working requirements of the equipment in a thousand-level cleanliness environment.

◆ The newly designed high-precision printing platform provides a guarantee for the consistency of printed film thickness, and the film thickness accuracy can reach ±1 micron.

◆ The CCD vision module adopts a linear motor gantry dual-drive structure to provide guarantees for equipment accuracy and stability.

◆ The LOT board function enhances the intelligent processing capabilities of the equipment.

Module introduction:

Substrate positioning module:

1. Full servo UVW module with advanced platform calibration algorithm to improve substrate alignment accuracy and stability.

2. High-precision vacuum adsorption, positioning and support mechanism to perfectly meet the clamping and positioning requirements of thick film printing process.

3. Provide vacuum negative pressure monitoring and vacuum breaking functions.

Robot handling module:

1. Avoid product contamination, effectively reduce the substrate contamination problem caused by powder loss during traditional belt conveyor, and is suitable for operation in a high-cleanliness environment.

2. The three-stage track conveying mechanism effectively improves product production efficiency.

CCD vision module:

1. The CCD vision module adopts a gantry dual-drive motion structure, which can effectively solve the problem of uneven force on both ends of the beam of the traditional transmission mechanism.

2. Both CCD X-axis and Y-axis are driven by linear motors, which greatly improves the visual positioning accuracy and efficiency.

Squeegee printing module:

1. Adjustable screen frame arm with scale to meet the needs of fast fixing of screens of different specifications.

2. Specially made one-lay one-scrape squeegee, and the squeegee head is adjustable in Y direction to meet the centering adjustment of substrates with different widths.

3. Adjustable Y-direction positioning mechanism to achieve fast switching of screens;

4. Innovative long-side printing method reduces squeegee length and improves squeegee force uniformity.

Squeegee pressure control module:

1. Multiple pressure control modes (drop control, closed-loop pressure control, normal pressure control, etc.) to meet the pressure setting requirements of the equipment under different processes.

2. The printing angle adaptive squeegee structure can fit the screen and achieve uniform pressure better.

3. Real-time pressure monitoring system to achieve closed-loop control of squeegee pressure.

Cleaning module:

1. Spray cleaning agent feeding system, which can realize precise control of cleaning agent through the software.

2. Programmable cleaning mode setting, which can realize intelligent cleaning operation.

3. The flexible wiping board structure can fit the screen in real time, which can better improve the cleaning effect.

Automatic paste feeding module:

1. It can be customized according to the size of the customer's paste tank to prevent poor printing caused by untimely manual paste feeding.

2. Automatically add paste to reduce labor costs.

3. Automatically prompt to replace the paste tank.

parameter:

| Machine Performance | |

| Repeat Position Accuracy | ± 8um@6σ,CPK≥2.0 |

| Repeat Print Accuracy | ±15um@6σ,CPK≥2.0 |

| Printing film thickness accuracy | ±1um |

| Printing thinnest thickness | 5um |

| Excluding cleaning and printing | 7sec |

| Processing CT | 4min |

| Line Change CT | 2min |

| Substrate Processing Parameters | |

| Maximum Laminate Dimension | Standard 270*70mm None-standard can be customized |

| Minimum Laminate Dimension | Standard 270*70mm None-standard can be customized |

| Laminate Thickness | 0.5-2mm |

| Mechanical Range of Capture | 560(X)*540(Y)mm |

| Maximum Laminate Weight | 1kg |

| Marginal Gap of Laminate | 0mm |

| Height over the Top | 0mm(can be customized) |

| Transmission Height | 900±40mm |

| Transmission Speed | (Control by section):1500mm/s(max) |

| Way of Transmission | Three-section transmission guide rail and manipulator handing |

| Transmission Direction | standard:From left to right From right to left can be customizable |

| Laminate Support Method | Vacuum platform |

| Laminate Clamping | Flexible side clamps and Vacuurm suction function |

| Printing Parameters | |

| Printing Speed | 10-200mm/sec |

| Printing Pressure control Method | 0.5~20Kg(pressure control) 0.01~10mm(position control) |

| Printing Mode | Single scraper printing Double scraper printing Inking left and printing right Inking right and printing left |

| Scraper Type | Rubber scraper/steel scraper (angle: 45/55/60) |

| Stripper Distance | 0~20mm |

| Stripper Speed | 0-20mm/sec |

| Size of Steel Mesh Frame | 470(X)*370(Y)mm~737(X)*737(Y)mm (Thickness:20-40mm) |

| Positioning Method of Steel Mesh | Manual compensation adjustment |

| Cleaning Parameters | |

| Cleaning Method | Dry wiping wet wiping vacuum |

| High Speed Cleaning | Integral & back and forth cleaning |

| Cleaning System | Top spray type |

| Cleaning Stroke | Generated automatically based on the length and width of the laminate |

| Cleaning Position | Posting-cleaning |

| Cleaning Speed | 10-200mm/sec |

| Consumption of Cleaning Fluid | Generated automatically. Manually adjustable |

| Consumption of Cleaning Paper | Generated automatically. Manually adjustable |

| Image Parameters | |

| Field of Vision of Image | 7 mm*5.5 mm |

| Camera Type | imported digital camera |

| Image Pickup System | Up-dawn Imaging, stepless adjustment of light source |

| Capture CT | 100ms |

| Type of Datum Point | Datum point of stanclard shapes Such as circle, square, rhombus, cross Bonding pad and special-shaped |

| Mark Size | 0.1-4 mm |

| Number of Marks | 2 pcs |

| Number of Fool. Proof Points | software configurable |

| Machine Parameter | |

| Power Requirement | AC:220±10%,50/60Hz 2.2KW |

| Requirement of Compressed Air | 4~6Kgf/cm² |

| Gas Consumption | About 5L/min |

| Temperature of Working Environment | -20°C-+45°C |

| Humidity of Working Environment | 30%~60% |

| Machine Height (Excluding tricolor light) | 1665 mm |

| Machine Length X-Direction | 1140 mm |

| Machine Width Y-Direction | 1155 mm |

| Machine Weight | About 900Kg |

|

|