| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Suneast |

| Model Number : | SEMI-08N|SEMI-10N|SEMI-13N |

| Certification : | CE、ISO |

| Price : | Negotiable |

| Payment Terms : | T/T |

| Delivery Time : | 25~50 days |

SEMI Series Modular Design Semiconductor Reflow Soldering Oven Hot Air System

Application:

Core Technology:

01 Hot air system with patent, efficient heat compensation ability, accurate temperature control accuracy

02 With nitrogen protection in the whole process, independent nitrogen control in each temperature zone, to prevent components oxidation during the welding process

03 Low oxygen content control in the furnace which will be within 50-200PPM during the whole process, to ensure good welding quality

04 Modular design, efficient cooling system, cooling slope can reach 0.5-6℃/S, to meet the requirements of each process cooling slope

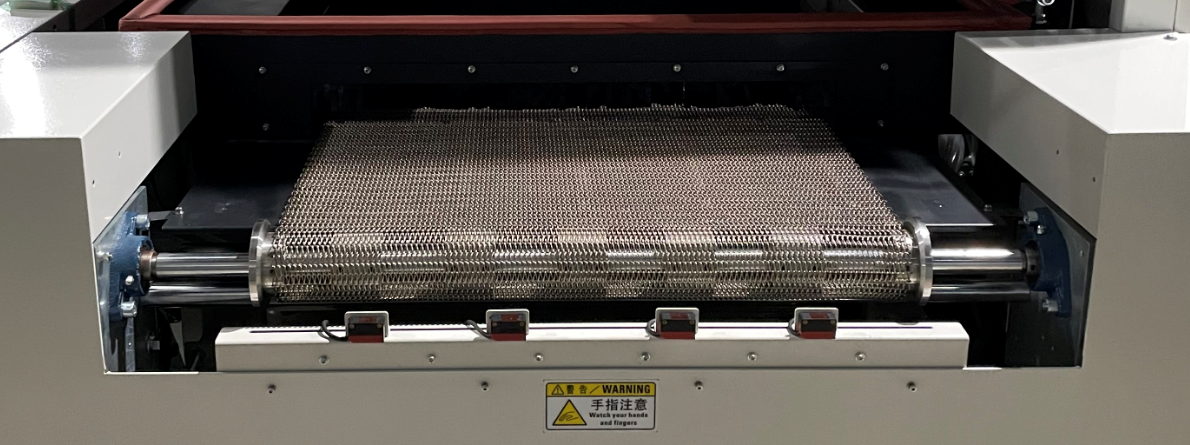

05 Fine mesh belt for smooth conveying, also for tiny components transmission, prevent falling, to ensure stable product quality

06 Efficient and clean treatment, to meet the requirements of dust-free workshop for semiconductor

Product Features:

CONVEYOR SYSTEM Special fine mesh belt transmission for semiconductor, for tiny components, to prevent falling and jamming |  |

HOT AIR SYSTEM MULTI-FREQUENCY CONTROL Multi-frequency converter control, more precise temperature control, the air flow range can be controlled from low to high, to ensure that the control system is stable and reliable |  |

ROSIN RECOVERY SYSTEM There’re independent rosin recovery devices at the inlet and outlet sides, and also for the preheating area, multistage filtration |  |

FULL NITROGEN PROTECTION SYSTEM, LOW OXYGEN CONTENT The nitrogen is charging in the whole process and controlled Independently in each process section; ultra-low oxygen concentration environment, and the oxygen content in the furnace can be within 50PPM to ensure excellent welding quality |  |

LOW NITROGEN CONSUMPTION Brand new furnace structure design, multi-layer heat insulation, closed-loop control of recovery system, effectively save the amount of nitrogen and save the use cost |  |

EFFICIENT HOT AIR CIRCULATION HEATING SYSTEM Multi-layer heat insulation design, high stability of thermal efficiency, low energy consumption, reduce production costs |  |

COOLING SYSTEM Cooling zone with high power cold water system to ensure optimal cooling slope |  |

CONTROL SYSTEM Super temperature control ability, to meet the packaging heating process profile of semiconductor |  |

HIGH CLEANLINESS Special clean room for R&D, thousand level of cleanliness, to meet the requirements of high cleanliness environment of semiconductor equipment |  |

CONVEYOR SYSTEM The software supports SECS/GEM semiconductor communication protocol, connects the intelligent factory information and control system, which can effectively realizes the functions of connection management, data collection, alarm, control status, equipment terminal service and message log, etc |  |

Product Parameters:

| Model No | SEMI-08N | SEMI-10N | SEMI-13N |

| Heating system | |||

| Heating zone structure | 8 heating zones, 16 heating modules | 10 heating zones, 20 heating modules | 13 heating zones, 26 heating modules |

| Heating zone length | 2950mm | 3670mm | 4750mm |

| Heating up time | 20min | 25min | 25min |

| Outlet Exhaust Diameter,valume | 2-Ø145,Exhaust demand 10m³/min x2 | ||

| Cooling system | |||

| Cooling type | Three cooling zones:forced water cooling | ||

| Cooling zone length | 1250mm | ||

| Chiller power | External Water chiller (Optional: connected to customer workshop cooling water) | ||

| Conveyor system | |||

| Conveyor Type | Fine mesh mesh belt (Optional: B-shaped mesh belt, force bone mesh belt) | ||

| Conveyor Direction | L→R,R→L | ||

| Conveyor Height | 900±20mm | ||

| Mesh belt width | 24" (Other width sizes can be customized.) | ||

| Component Height | 20mm | ||

| Conveyor Speed | 300mm-2000mm/min | ||

| Control system | |||

| Power | AC3Ø 5W 380V 50/60HZ | ||

| Total Power | 70KW | 89KW | 118KW |

| Startup Power | 35KW | 38KW | 42KW |

| Normal consumption | 10KW | 12KW | 14KW |

| Temp Control Range | Room temperature to 320℃ | ||

| Control type | PC+PLC Control system | ||

| Temp Control accuracy | ±1℃ | ||

| PCB Temp Deviation | ±1.5℃ | ||

| Data Storage | Process Data and status stotage | ||

| Power Outage Protection | Equipped with UPS | ||

| Operation Interface | Windows Chinese simplified, English online free switching | ||

| N2 area | Full nitrogen filling | ||

| Secs/Gemcommunication protocol | Standard | ||

| MES communication protocol | Standard | ||

| Computer | Commercial computer | ||

| Machine Parameter | |||

| Dimension(LxWxH) | 5680x1710x1650mm | 6400*1710*1650mm | 7500*1710*1650mm |

| Weight | 2400-2600kg | 3200-3400kg | 3600-3800kg |

| Flux recovery system | Standard | ||

| Color | Bright wrinkled white | ||

Notices:

1.Power requirements:

①Three phase five wire: voltage 380V, frequency 50/60HZ;

②Wire diameter above 25mm², leakage protection switch 160A, leakage protection switch leakage capacity 150-200mA.

2.The ground is required to withstand a pressure of 1000kg/m²

3.External ventilation requirements: air duct Ø145mm, ventilation volume 15-20M³/min.

|

|