| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Suneast |

| Model Number : | UXT-350|450|610 |

| Certification : | CE、ISO |

| Price : | Negotiable |

| Payment Terms : | T/T |

| Delivery Time : | 25~50 days |

UXT Series Lead-free Wave Soldering Equipment DIP Technology

UXT series oven is based on customer demand and adopts modular, digital and humanized design. With superiority in function, performance, stability, reliability, security, maintainability, operability and humanization, it doesn't only reduce the operating cost, but also provides qualified products for quality, quantity and production with strong guarantee. It can be described as the "peak" work in the field of Wave soldering products, and the preferred "brand products" for customer investment.

Feature:

Application range:

Wave soldering equipment is used to solder through-hole components and circuit boards through high-temperature liquid solder waves on printed boards with pre installed plug-in components. Wave soldering is widely used in the electronic product manufacturing industry, including consumer electronics, communication equipment, household appliances, power supplies, automotive electronics, medical equipment, industrial automation, energy and other industries

Overall diagram:

01 Buffer system

02 Flux supply system

03 Exhaust fan

04 Flux spray system

05 LCD

06 Pre-heater

07 Solder pot lifting unit

08 Dual wave solder pot

09 Cooling system

10 Angle adjustment controller

11 Finger cleaning system

12 Conveyor system

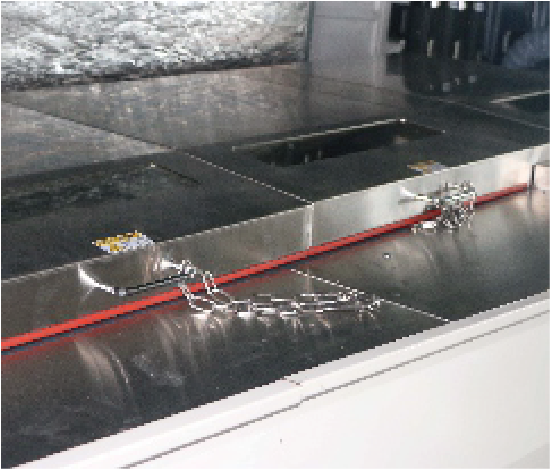

| Integrated spray fluxer unit (selective spray device is optional) |  |

| Drawer type and modular structure preheating zones |  |

| Cast iron soldering pot with special anti-corrosion coating |  |

| Manual width adjustment with digital display |  |

| Solder pot electric/manual lifting in and out |  |

Product Parameters:

| Modol NO | UXT-350 | UXT-450 | UXT-610 |

| Dimension:LxWxH(mm) | 4350*1480*1750 | 4350*1580*1750 | 4350*1740*1750 |

| Weigh | Approx.1800kg | Approx.1950kg | Approx.2150kg |

| Power Supply | 3PH 380V 50HZ | 3PH 380V 50HZ | 3PH 380V 50HZ |

| Startup Power | 32KW | 32KW | 45KW |

| Operation Power Consumption | Approx.8KW | Approx.8.5kW | Approx.11KW |

| Control System | PC+PLC | PC+PLC | PC+PLC |

| Spraying movement | Step motor | Step motor | Step motor |

| Spray Pressure | 0.2Mpa-0.4Mpa | 0.2Mpa-0.4Mpa | 0.2Mpa-0.4Mpa |

| Flux Flow Arrange | Option | Option | Option |

| Auto Fill Flux | Standard | Standard | Standard |

| Exhaust | Top exhaust +Side exhaust | Top exhaust +Side exhaust | Top exhaust +Side exhaust |

| Exhaust Ducting Diameter(mm) | Φ250 | Φ250 | Φ250 |

| Exhaust Capacity | 30m³/min | 30m³/min | 30m³/min |

| Preheating Mode | Hot air Convection / IR | Hot air Convection / IR | Hot air Convection/IR |

| Control Mode | PID | PID | PID |

| Preheating Zone Number | 3 | 3 | 3 |

| Preheating Length(mm) | 1800 | 1800 | 1800 |

| Preheating Temperature | Room temperature~200℃ | Room temperature~200℃ | Room temperature~200℃ |

| Warm-up Time(min) | Approx.12min (setting:150℃) | Approx.12min (setting:150℃) | Approx.12min (setting:150℃) |

| Blower Motor | 250W 3PH 220VAC | 250W 3PH 220VAC | 250W 3PH 220VAC |

| PCB Width(mm) | 50-350 | 50-450 | 50-610 |

| Conveyor Direction | L-R(Option:R-L) | L-+R(Option:R-L) | L-R(Option:R-L) |

| Conveyor Speed(mm/min) | 500~1800 | 500~1800 | 500-1800 |

| Conveyor Height(mm) | 750±20 | 750±20 | 750±20 |

| Available Component Heigh (mm) | Top 120(Option:240) Bottom 15 | Top 120(Option:250) Bottom 15 | Top 120(Option:250) Bottom 15 |

| Conveyor Speed Control Mode | Closed loop stepless speed regulation by Inverter | Closed loop stepless speed regulation by Inverter | Closed loop stepless speed regulation by Inverter |

| Fingers | Spring Pressing Finger/D-40Type Finger /Double-hook Finger/Heavy type double hook finger, Options | Heavy type double hook finger/ Option:Special jig for fixture | |

| Conveyor Angle | 4-7° | 4-7° | 4-7° |

| Type of solder Pot | Motor drive | Motor drive | Motor drive |

| Solder Pot Material | Casting Iron | Casting Iron | Casting Iron |

| Wave Height Adjustment | Inverter: Digital Control by PC | ||

| Cooling Method | Air Cooling Option:Water cooling | ||

| Heater Power | 13.5KW | 13.5KW | 18KW |

| Solder Pot Temperature | 300℃ | 300℃ | 300℃ |

| Solder Pot Capacity | Approx.480KG | Approx.550KG | Approx.640KG |

| Wave Drive Power | 180Wx23PH220VAC | 180W*23PH220VAC | 180Wx23PH220VAC |

| Solder Pot Warm-up Time | Approx.150min (setting:250℃) | Approx.150min (setting:250℃) | Approx.150min (setting:250℃) |

| Temperature Control Mode | PID | PID | PID |

| Finger Cleaning System | Brush | Brush | Brush |

Notices:

1.Power requirements:

①Three phase five wire: voltage 380V, frequency 50/60HZ

②The wire diameter requirement is 16mm², with a leakage protection switch of 125A and a leakage capacity of 150-200mA

2.The ground is required to withstand a pressure of 1000kg/m²

3.External air exhaust requirements:

①Spray: air duct Ø 250mm, exhaust air volume 30M³/min;

②The exhaust air volume for the tin furnace outlet Ø250 and the tail cover outlet Ø 150 is about 15M³/min

|